Springtime Maintenance for Your RV Trailer

Here in the Midwest, winter is loosening its grip, and 5th wheel and travel trailer owners are beginning to get their RVs ready for the road. While there are lots of details in getting the interior of the RV ready for road trips, trailer owners will want to use this time to also make sure their running gear is up to the task. After all, since an RV is a house on wheels, the running gear is a key component in the house foundation. It should not be neglected when it comes time for maintenance on your RV.

Leaf Spring Suspension Systems

The vast majority of travel trailers and 5th wheels use a leaf spring suspension to absorb road shock. Each leaf is made of steel springs that are stacked on top of each other and attach to the axle with U-bolts. Here are a few inspection tips for the leaf springs:

• Look to see if the trailer is leaning to one side or the other. This could be the result of a weight imbalance in the trailer or a sign of a suspension issue.

• Check the leaf springs for cracks or breaks in the steel itself.

• Check the U-bolts and nuts to make sure the attachment of the leaf spring to the axle is secure.

Suspension Frame Hanger

The leaf springs are attached to the trailer frame with frame hangers and hardware. The frame hangers are welded to the trailer frame. A quick inspection of the hanger can indicate whether there are any cracks in it. The weld of the hanger to the frame should also be inspected to make sure it is still solid. If you see any cracks in the hanger or the weld, this will need to be addressed.

Center Equalizer

Tandem and triple axle suspension systems use an equalizer to distribute weight between the axles. The equalizer is made of steel and is attached to the frame hanger. It simply rocks back and forth and is attached to the leaf springs with shackle brackets and bolts. It can be visibly inspected for any cracks in the steel or worn attachment points, evidenced by the holes in the equalizer being wallowed out or elongated.

Shackle Brackets and Bolts

The leaf springs are attached to the hangers with shackle brackets, bolts, and plastic bushings. These components serve as pivot points that reduce the friction in the suspension system. Because of this, it is very common for them to wear over time. The standard in the industry is a ¼” shackle bracket, a standard bolt, and a plastic bushing that is located inside the leaf spring and steel equalizer eye.

The plastic bushing will wear over time which can then cause the ¼” shackle bracket hole to wallow out. If the wear is not detected, the shackle bracket hole can eventually fail. This will then cause the leaf spring to drop down and make it difficult to tow the unit. For that reason, catching wear on shackle brackets is extremely important.

Helpful Upgrades

There are several upgrades that can be done to the suspension system that can help manage wear as well as improve the towing characteristics of the trailer.

Upgraded Equalizer

The traditional steel equalizer simply rocks back and forth and doesn’t help absorb road shock. MORryde’s CRE3000 uses rubber to cushion and absorb road shock as well as increase the travel of the suspension system. This combination of added travel with the rubber spring helps absorb more road shock and provide smoother towing. Installation is strictly bolt-on and can be done in just over one hour.

Heavy-Duty Shackle Kit

The MORryde Heavy-Duty Shackle Kit is one of the best investments you can make in the running gear of the trailer. It consists of ½” shackle brackets, bronze bushings and a greaseable bolt. This combination is a superior upgrade to the wear-prone plastic bushings and ¼” brackets. You need to get the unit jacked up and the weight off the axles to perform the installation which will take about 4-5 hours. It’s time well spent to head off any potential problems. Check out our YouTube video that explains just how important a MORryde Shackle Kit upgrade is for your trailer.

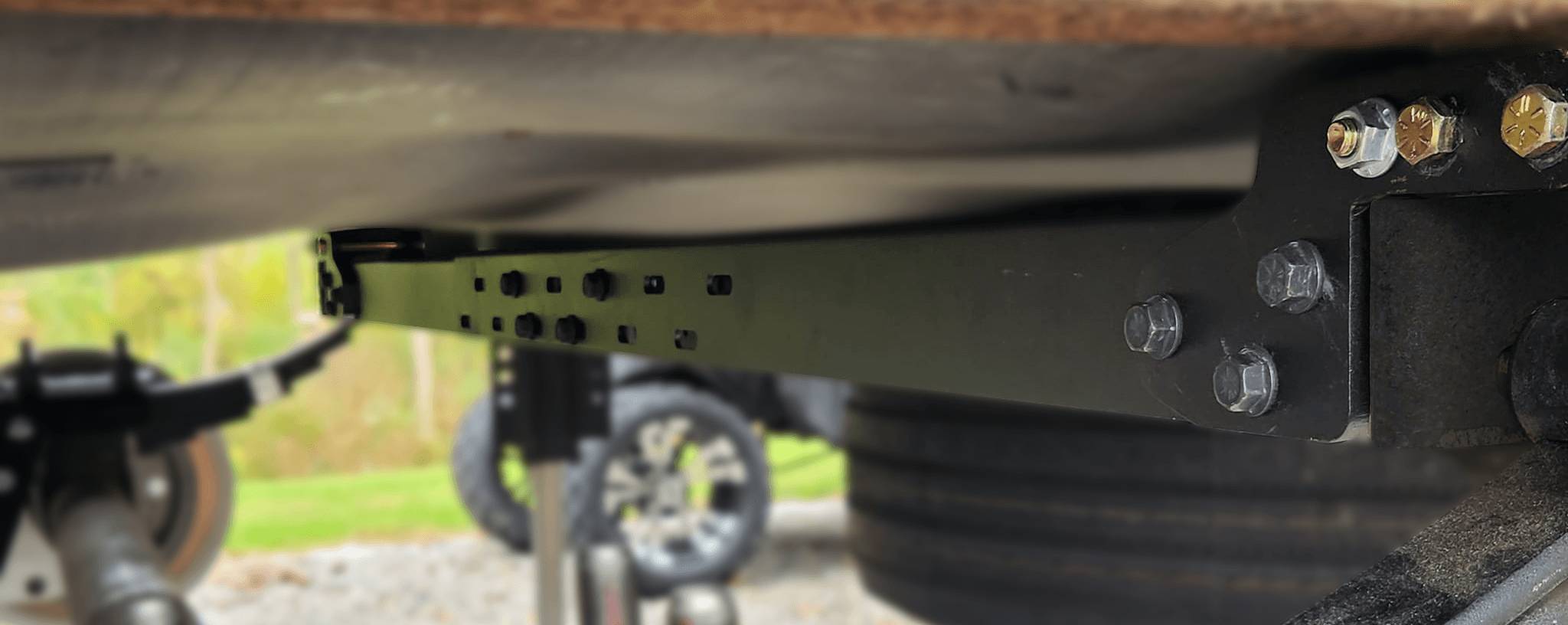

Heavy-Duty Crossmember

Every trailer has frame crossmembers, but very few have any near the leaf spring hangers. A heavy-duty bolt-in crossmember like the MORryde X-Factor can provide much-needed lateral support to the frame hangers. A crossmember can be installed at each of the frame hangers, helping reduce the lateral strain on the frame and providing a stronger foundation.

Using this time of year to inspect and possibly upgrade your suspension and running gear will go a long way in helping you further enjoy your RV and the RV lifestyle. You’ll have peace of mind that wherever you choose to travel, your house on wheels is ready to go.

It looks like your installation might require some modifications.

Please contact our parts department to discuss options that may work for you.