Our business rides on service, and in the MORryde chassis division, it starts with delivering a solid vehicle foundation. Partnering with manufacturers from five different states and a variety of industries, we’ve become a leader in chassis modifications, including wheel base alterations, chassis upfits, and component installation.

OVERVIEW

CAPABILITIES

Our business rides on service, and in the MORryde chassis division, it starts with delivering a solid foundation. Partnering with manufacturers, we deliver on a wide range of chassis services, including:

SPECIALTY FRAMES:

- FRAME EXTENSIONS

- CUSTOM BUILDS

- FRONT-WHEEL DRIVE CONVERSIONS

- RAISED-RAIL FRAME

- LOW-FLOOR UPFITTING

MODIFICATIONS:

- WHEELBASE

- SUSPENSION

- DRIVELINE

- ALTERNATIVE FUEL CONVERSIONS

INSTALLATIONS:

- TRUSS

- SUBFLOOR

- SLIDEOUTS

- SUSPENSION

- BRAKE RETARDERS

- HYDRAULIC LEVELING SYSTEMS

- GENERATOR TRAYS & BATTERY TRAYS

CERTIFICATIONS

INDUSTRY CERTIFIED

MORryde, a NTEA member and a NHTSA registrar, is considered an intermediate stage manufacturer. We follow all applicable FMVSS requirements and label each modified chassis as required by NHTSA. Additionally, every modified chassis adheres to Ford QVM guidelines, as presented in bulletins, including Q14, Q18, Q40 and Q140. QVM certification applies only to the final stage manufacturer; however, MORryde complies with all appropriate QVM guidelines. Our customers are audited routinely for QVM compliance, and during those audits, MORryde’s work is inspected and routinely determined to meet or exceed the QVM standard.

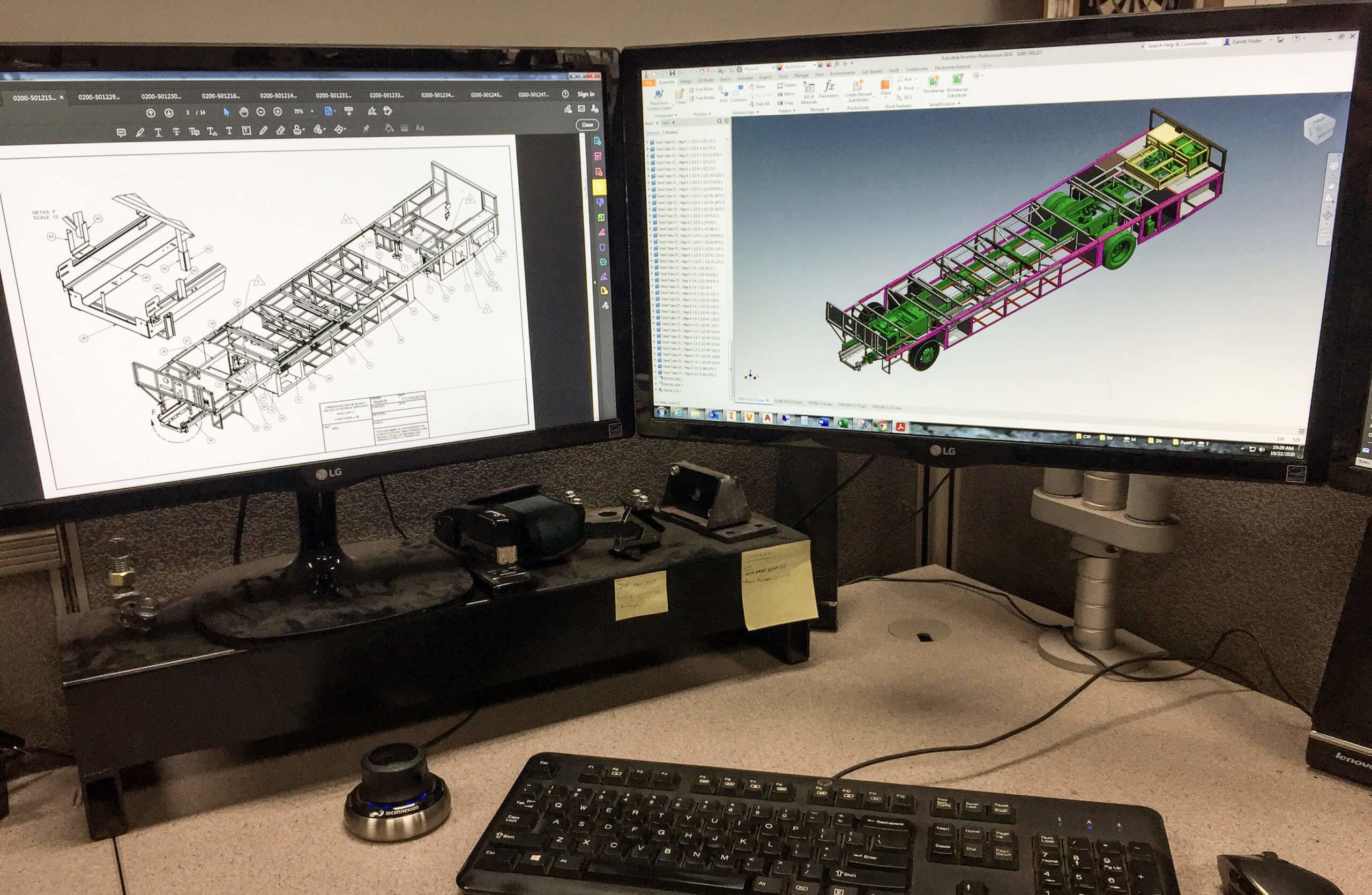

ENGINEERING & DESIGNING

WE BUILD BETTER TOGETHER

We know every customer is different, so we go the extra mile to deliver on each individual need. Applying years of engineering expertise and chassis knowledge, MORryde utilizes the latest 3D software for accurate modeling information and incorporates FEA capabilities in product development. In short, we take great pride in being your partner in chassis solutions.

CHASSIS UPFITTING

CONSIDER US A PART OF YOUR PRODUCTION LINE

We’re here to make production easier, so it means a lot to us when our customers look to the MORryde chassis division to install the primary chassis structure, right down to the trusses, outriggers, baggage compartments, leveling jacks and slideouts. During this process, we work closely with each manufacturer to identify critical dimensions. We utilize custom-engineered, precision-built fixtures and tables to assemble and hold these details.

WHEELBASE MODIFICATIONS

A LEADING CHASSIS MODIFIER

MORryde is the leading chassis modifier for the RV and transit bus industries with chassis being shipped to us from five different states. From truck frames to the popular E-series, our experience allows us to work on a complete range of chassis, including the International and Freightliner chassis.

OEM-matching harnesses, fittings and plugs are used whenever possible for reliability and service. Thanks to our fabrication capabilities, we’re able to produce many components, which allows us to quickly adapt to changing product lines or new model introductions.

DRIVELINE & BALANCING

A WELL-BALANCED DRIVESHAFT STARTS HERE

MORryde driveline modifications follow procedures and guidelines set by Dana Spicer, Ford and other chassis manufacturers. Our employees are trained on driveshaft balancing, factoring in proper lengths, speeds and angles to ensure a safe and functional driveline. Every driveshaft is measured for run-out, and the system is balanced just as if it would be installed on a completed chassis.

SUSPENSION SYSTEMS

SUSPENSION UPGRADES

As part of the chassis modification process, we often install various suspension upgrades. These can range from our patented suspension systems, the RL and RS, all the way up to four-corner, air-ride suspension systems. We also offer installations of other components including leaf springs, coil springs, helper springs, lift blocks and driveline brakes, along with alignment service.

QUALITY CONTROL

REPEATABLE QUALITY STARTS WITH A PROCESS

Every MORryde-modified chassis goes through a final inspection process. Trained inspectors use a formal Quality Control Plan, and should a quality issue arise, each scenario is documented, reviewed and tracked following Six Sigma guidelines. Additionally, MORryde quality representatives visit our customers on a routine schedule, allowing us to talk with production personnel to identify issues before they build up. In the end, our goal is repeatable quality.